Cognitive mapping the topic of Total Quality

Management (TQM)

Joseph

Kim-keung Ho

Independent Trainer

Hong Kong, China

Abstract: The topic of Total Quality

Management (TQM) in the subject of business management is complex. By making

use of the cognitive mapping technique to conduct a brief literature review on

the Total Quality Management topic, the writer renders a systemic image on the

topic of Total Quality Management. The result of the study, in the form of a

cognitive map on Total Quality Management, should be useful to those who are

interested in the topics of cognitive mapping, literature review and Total

Quality Management.

Key words: Total

Quality Management (TQM), cognitive mapping, literature review

Introduction

As a

topic in business management, Total Quality Management (TQM) is complex. It is

thus useful to employ some learning tool to conduct its study, notably for

literature review purpose. For a teacher in research methods, systems thinking

and management, the writer is specifically interested

in finding out how the cognitive mapping technique can be employed to go

through a literature review on Total

Quality Management. This literature review exercise is taken up and reported in

this article.

On the cognitive mapping exercise for

literature review

Literature

review is an important intellectual learning exercise, and not just for doing

final year dissertation projects for tertiary education students. On these two

topics of intellectual learning and literature review, the writer has compiled

some e-learning resources. They are the Managerial

intellectual learning Facebook page and the Literature on literature review Facebook page. Conducting

literature review with the cognitive mapping technique is not novel in the

cognitive mapping literature, see Eden and Simpson (1989), Eden, Jones and Sims

(1983), Open University (n.d) and the Literature

on cognitive mapping Facebook page. In this article, the specific steps

involved in the cognitive mapping exercise are as follows:

Step 1:

gather some main points from a number of academic journal articles on Total

Quality Management. This result in the production of a table (Table 1) with the

main points and associated references.

Step 2: consolidate the main points from Table 1 to come up with

a table listing the cognitive map variables (re: Table 2).

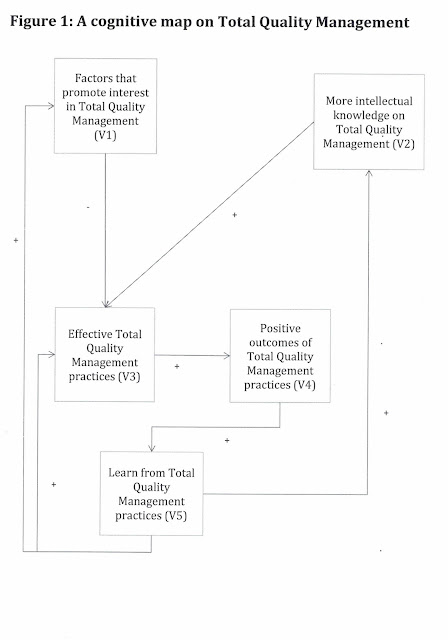

Step 3: link

up the cognitive map variables in a

plausible way to produce a cognitive map (re: Figure 1) on the topic under

review.

The next

section applies these three steps to produce a cognitive map on Total Quality

Management.

Descriptions of cognitive map variables on

the Total Quality Management (TQM) topic

From the

reading of some academic articles on Total Quality Management, a number of main

points (e.g., viewpoints, concepts and empirical findings) were gathered by

the writer. They are shown in Table 1

with explicit referencing on the points.

Table 1: Main

points from the Total Quality Management literature and referencing

Main points from the Total Quality

Management literature

|

Referencing

|

Point

1: "The quality idea has been around for hundreds of years. The

discerning customer in shops and market-places centuries ago applied 'quality

techniques', prodding and turning fruits and vegetables testing for firmness,

freshness and fitness for the purpose of consumption".

|

Flood,

R.L. 1993. Beyond TQM, Wiley,

Chichester.

|

Point

2: "TQM wants to change the traditional management style. Handing down

responsibility, allowing for autonomy, and promoting local decision making

are all part of the new approach that TQM calls for. Greater motivation and

creativity are expected".

|

Flood,

R.L. 1993. Beyond TQM, Wiley,

Chichester.

|

Point

3: "Total Quality Management is "continuous improvement, involve

all operations at all levels, undertake performance measurement, focus on

leadership, teamwork and employee participation and motivation, take a whole

system perspective".

|

Flood,

R.L. 1993. Beyond TQM, Wiley,

Chichester.

|

Point

4: "Each quality guru has their own knowledge base and interests. Each

has worked in different situations, and several have contributed in

contrasting eras".

|

Flood,

R.L. 1993. Beyond TQM, Wiley,

Chichester.

|

Point

5: "The [TQM] gurus have provided well for our technical mechanistic

needs. One area they say little about in respect to technical interests,

however, is organisational design".

|

Flood,

R.L. 1993. Beyond TQM, Wiley,

Chichester.

|

Point

6: "Improved quality should shrink costs and thus yield a positive

outcome for financial performance. Moreover, superior-quality products or

services should enhance the retention rate of existing customers and attract

new ones, thus strengthening market share and revenue".

|

Chaudary,

S., S. Zafar and M. Salman. 2015. "Does total quality management still

shine? Re-examining the total quality management effect on financial

performance" Total Quality

Management & Business Excellence 26(7), Routledge: 811-824.

|

Point

7: "TQM results in process improvements both in the manufacturing and

service sectors, which lead to higher profits through product reliability and

costs cut through process efficiency".

|

Chaudary,

S., S. Zafar and M. Salman. 2015. "Does total quality management still

shine? Re-examining the total quality management effect on financial

performance" Total Quality

Management & Business Excellence 26(7), Routledge: 811-824.

|

Point

8: TQM can be defined as "a set of instruments employed by the firm's

management that aim to provide better value to customers by recognising their

observable and hidden needs (which are sensitive to changing markets) and

improving the efficiency of the procedures that generate the product or

service".

|

Chaudary,

S., S. Zafar and M. Salman. 2015. "Does total quality management still

shine? Re-examining the total quality management effect on financial

performance" Total Quality

Management & Business Excellence 26(7), Routledge: 811-824.

|

Point

9: "Lascelles and Dale... identify six TQM adoption levels: (1) uncommitted,

(ii) drifters, (iii) tool purchasers, (iv) improvers, (v) award winners, and

(vi) world class. These levels are not stages of TQM as much as they reflect

how a firm responds to TQM".

|

Chaudary,

S., S. Zafar and M. Salman. 2015. "Does total quality management still

shine? Re-examining the total quality management effect on financial

performance" Total Quality

Management & Business Excellence 26(7), Routledge: 811-824.

|

Point

10: "TQM is the mutual cooperation of everyone in an organization and associated business

processes to produce products and services which meet the needs and

expectations of customers".

|

Gunasekaran.

1999. "Enablers of total quality management implementation in

manufacturing: a case study" Total

Quality Management 10(7): 987-996.

|

Point

11: Teamwork and employee involvement are "the key enablers of

TQM". "Cultural change, focus, employee ownership of the processes,

and strategic partnership with customers and suppliers are critical to the

implementation of TQM".

|

Gunasekaran.

1999. "Enablers of total quality management implementation in

manufacturing: a case study" Total

Quality Management 10(7): 987-996.

|

Point

12: "....managers can implement TQM in any organization - manufacturing,

service, nonprofit, or government - and that it generates improved products

and services, reduced costs, more satisfied customers and employees, and

improved bottom line financial performance".

|

Powell,

T.C. 1995. "Total Quality Management as Competitive Advantage: A Review

and Empirical Study" Strategic

Management Journal 16(1) January: 15-37.

|

Point

13: "In Japan, TQM produced such managerial innovations as quality

circles, equity circles, supplier partnerships, cellular manufacturing,

just-in-time production, and hoshin planning".

|

Powell,

T.C. 1995. "Total Quality Management as Competitive Advantage: A Review

and Empirical Study" Strategic

Management Journal 16(1) January: 15-37.

|

Point

14: "American firms began to take serious notice of TQM around 1980,

when some U.S. policy observers argued that Japanese manufacturing

quality had equated or exceeded U.S. standards, and warned that

Japanese productivity would soon surpass that of American firms".

|

Powell,

T.C. 1995. "Total Quality Management as Competitive Advantage: A Review

and Empirical Study" Strategic

Management Journal 16(1) January: 15-37.

|

Point

15: "... some employees resist or

even subvert TQM, finding it

ideological or faddish. Furthermore, TQM entails substantial time investments

from managers, it is expensive (especially for training and meetings), it

rarely produces short-term results, it demands intense CEO commitment, and it

makes unrealistic assumption about most organizations' capacities to

transform their cultures".

|

Powell,

T.C. 1995. "Total Quality Management as Competitive Advantage: A Review

and Empirical Study" Strategic

Management Journal 16(1) January: 15-37.

|

Point

16: "Despite the increase in academic studies into total quality

management (TQM) during the past decade, there still seem to be relatively few empirical studies that

either confirm or contradict any of

the widely accepted theories".

|

Black,

S. and L.J. Porter. 1995. "An empirical model for total quality

management" Total Quality

Management 6(2): 149-164.

|

Point

17: "The Malcolm Baldrige National Quality Award in the US is a

generally accepted TQM framework. However, the Malcolm Baldrige Award are not

based on empirical evidence".

|

Black,

S. and L.J. Porter. 1995. "An empirical model for total quality

management" Total Quality

Management 6(2): 149-164.

|

Point

18: "As is inevitable for any idea that enjoys wide popularity in

managerial and scholarly circles, total quality management has come to mean

different things to different people".

|

Hackman,

J.R. 1995. "Total Quality Management: Empirical, Conceptual, and

Practical Issues" Administrative Science Quarterly 40: 309-342.

|

Point

19: "Deming, Ishikawa, and Juran share the view that an organization's

primary purpose is to stay in business, so that it can promote the

stability of the community, generate

products and services that are useful to customers, and provide a setting for

the satisfaction and growth of organization members".

|

Hackman,

J.R. 1995. "Total Quality Management: Empirical, Conceptual, and

Practical Issues" Administrative Science Quarterly 40: 309-342.

|

Point

20: "A fundamental premise of TQM is that the cost of poor quality (such

as inspection, rework, lost customers, and so on) are far greater than the

costs of developing processes that produce high-quality products and

services".

|

Hackman,

J.R. 1995. "Total Quality Management: Empirical, Conceptual, and

Practical Issues" Administrative Science Quarterly 40: 309-342.

|

Point

21: "Employees naturally care about the quality of work they do and will

take initiatives to improve it - so long as they are provided with the tools and training that are needed

for quality improvement, and management pays attention to their ideas".

|

Hackman,

J.R. 1995. "Total Quality Management: Empirical, Conceptual, and

Practical Issues" Administrative Science Quarterly 40: 309-342.

|

Point

22: "..organizations are systems of highly interdependent parts, and the central

problems they face invariably cross traditional functional lines".

|

Hackman,

J.R. 1995. "Total Quality Management: Empirical, Conceptual, and

Practical Issues" Administrative Science Quarterly 40: 309-342.

|

Point

23: "When looking at the development and scope of IE [Industrial

Engineering], most of its techniques seem to "fit" well with the

modern quality concept of integrating people and physical operating systems,

through effective system modification and/or redesign".

|

Lo,

V.H.Y. and D. Sculli. 1995. "Industrial engineering and TQM" Training for Quality 3(3), MCB

University Press: 4-7.

|

Point

24: "IE [Industrial Engineering] techniques have evolved with the direct objective of

achieving particular goals in designing, implementing and effectively maintaining operating systems, TQM, on the

other hand, is essentially a system whereby the qualities of a product, or service are maintained and

enhanced through economic considerations".

|

Lo,

V.H.Y. and D. Sculli. 1995. "Industrial engineering and TQM" Training for Quality 3(3), MCB

University Press: 4-7.

|

Point

25: "Although there is evidence that supports the effectiveness of TQM

initiatives in organisations, a large number of studies have shown that

between 60% and 80% of TQM

initiatives fail, or fail to have

shown significant impact on business performance".

|

Antony,

J., C. Fergusson, S. Warwood and J.H.Y. Tsang. 2004. "Comparing total

quality management success factors in UK manufacturing and service

industries: some key findings from a survey" Journal of Advances in Management Research 1(2): 32-45.

|

Point

26: "Total quality management (TQM) is abstract, and perhaps subjective,

and hence defining it in comprehensive terms and a unique universally

acceptable language is almost impossible".

|

Mani,

T.P., N. Murugan and C. Rajendran. 2003. "Classical approach to

contemporary TQM: an integrated

conceptual TQM model as perceived in Tamil classical literature" Total Quality Management 14(3),

Routledge: 605-636.

|

Point

27: "The paradigm of TQM applies to both the manufacturing and the

service sectors. Of late, with the integration of Organizational Development

(OD) into the Quality System, the TQM philosophy and approaches have started

establishing roots in Human Resources Development".

|

Mani,

T.P., N. Murugan and C. Rajendran. 2003. "Classical approach to

contemporary TQM: an integrated

conceptual TQM model as perceived in Tamil classical literature" Total Quality Management 14(3),

Routledge: 605-636.

|

Point

28: "Dedication to the customers, internal as well as external, should

be the critical theme of the service industry. Six general targets for

serving the customer are high quality, flexibility, service, low cost, quick

response and minimal variability".

|

Mani,

T.P., N. Murugan and C. Rajendran. 2003. "Classical approach to

contemporary TQM: an integrated

conceptual TQM model as perceived in Tamil classical literature" Total Quality Management 14(3),

Routledge: 605-636.

|

With a

set of main points collected, the writer produces a set of cognitive map

variables. These variables are informed by the set of main points from Table 1.

These variables are presented in Table 2.

Table 2:

Cognitive map variables based on Table 1

Cognitive

map variables

|

Literature

review points

|

Variable

1: Factors that promote interest in Total Quality Management

|

Point 1: "The quality idea has been

around for hundreds of years. The discerning customer in shops and

market-places centuries ago applied 'quality techniques', prodding and

turning fruits and vegetables testing for firmness, freshness and fitness for

the purpose of consumption".

Point 13: "In Japan, TQM produced

such managerial innovations as quality circles, equity circles, supplier

partnerships, cellular manufacturing, just-in-time production, and hoshin

planning".

Point 14: "American firms began to

take serious notice of TQM around 1980, when some U.S. policy observers

argued that Japanese manufacturing quality

had equated or exceeded U.S.

standards, and warned that Japanese productivity would soon surpass that of

American firms".

Point 15: "... some employees

resist or even subvert TQM, finding it ideological or faddish.

Furthermore, TQM entails substantial time investments from managers, it is

expensive (especially for training and meetings), it rarely produces

short-term results, it demands intense CEO commitment, and it makes

unrealistic assumption about most organizations' capacities to transform

their cultures".

Point 18: "As is inevitable for any

idea that enjoys wide popularity in managerial and scholarly circles, total

quality management has come to mean different things to different

people".

|

Variable

2: More intellectual knowledge on Total Quality Management

|

Point

3: "Total Quality Management is "continuous improvement, involve

all operations at all levels, undertake performance measurement, focus on

leadership, teamwork and employee participation and motivation, take a whole

system perspective".

Point

5: "The [TQM] gurus have provided well for our technical mechanistic

needs. One area they say little about in respect to technical interests,

however, is organisational design".

Point

8: TQM can be defined as "a set of instruments employed by the firm's

management that aim to provide better value to customers by recognising their

observable and hidden needs (which are sensitive to changing markets) and

improving the efficiency of the procedures that generate the product or

service".

Point

9: "Lascelles and Dale... identify six TQM adoption levels: (1) uncommitted,

(ii) drifters, (iii) too purchasers, (iv) improvers, (v) award winners, and

(vi) world class. These levels are not stages of TQM as much as they reflect

how a firm responds to TQM".

Point

10: "TQM is the mutual cooperation of everyone in an organization and associated business

processes to produce products and services which meet the needs and

expectations of customers".

Point

19: "Deming, Ishikawa, and Juran share the view that an organization's

primary purpose is to stay in business, so that it can promote the

stability of the community, generate

products and services that are useful to customers, and provide a setting for

the satisfaction and growth of organization members".

Point

20: "A fundamental premise of TQM is that the cost of poor quality (such

as inspection, rework, lost customers, and so on) are far greater than the

costs of developing processes that produce high-quality products and

services".

Point

21: "Employees naturally care about the quality of work they do and will

take initiatives to improve it - so long as they are provided with the tools and training that are needed

for quality improvement, and management pays attention to their ideas".

Point

22: "..organizations are systems of highly interdependent parts, and the central

problems they face invariably cross traditional functional lines".

Point

23: "When looking at the development and scope of IE [Industrial

Engineering], most of its techniques seem to "fit" well with the

modern quality concept of integrating people and physical operating systems,

through effective system modification and/or redesign".

Point

24: "IE [Industrial Engineering] techniques have evolved with the direct objective of

achieving particular goals in designing, implementing and effectively maintaining operating systems, TQM, on the

other hand, is essentially a system whereby the qualities of a product, or service are maintained and

enhanced through economic considerations".

Point

26: "Total quality management (TQM) is abstract, and perhaps subjective,

and hence defining it in comprehensive terms and a unique universally

acceptable language is almost impossible".

Point

27: "The paradigm of TQM applies to both the manufacturing and the

service sectors. Of late, with the integration of Organizational Development

(OD) into the Quality System, the TQM philosophy and approaches have started

establishing roots in Human Resources Development".

|

Variable

3: Effective Total Quality Management practices

|

Point

2: "TQM wants to change the traditional management style. Handing down

responsibility, allowing for autonomy, and promoting local decision making

are all part of the new approach that TQM calls for. Greater motivation and

creativity are expected".

Point

4: "Each quality guru has their own knowledge base and interests. Each

has worked in different situations, and several have contributed in

contrasting eras".

Point

11: Teamwork and employee involvement are "the key enablers of

TQM". "Cultural change, focus, employee ownership of the processes,

and strategic partnership with customers and suppliers are critical to the

implementation of TQM".

Point

28: "Dedication to the customers, internal as well as external, should

be the critical theme of the service industry. Six general targets for

serving the customer are high quality, flexibility, service, low cost, quick

response and minimal variability".

|

Variable

4: Positive outcomes of Total Quality Management practices

|

Point 6: "Improved

quality should shrink costs and thus yield a positive outcome for financial

performance. Moreover, superior-quality products or services should enhance

the retention rate of existing customers and attract new ones, thus

strengthening market share and revenue".

Point 7: "TQM results in process improvements both in the

manufacturing and service sectors, which lead to higher profits through

product reliability and costs cut through process efficiency".

Point 12: "....managers can implement TQM in any organization -

manufacturing, service, nonprofit, or government - and that it generates

improved products and services, reduced costs, more satisfied customers and

employees, and improved bottom line financial performance".

Point 15: "...

some employees resist or even

subvert TQM, finding it ideological or

faddish. Furthermore, TQM entails substantial time investments from managers,

it is expensive (especially for training and meetings), it rarely produces

short-term results, it demands intense CEO commitment, and it makes

unrealistic assumption about most organizations' capacities to transform

their cultures".

|

Variable

5: Learn from Total Quality Management practices

|

Point 16: "Despite the increase in

academic studies into total quality management (TQM) during the past decade, there

still seem to be relatively few

empirical studies that either confirm

or contradict any of the widely accepted theories".

Point 17: "The Malcolm Baldrige

National Quality Award in the US is a generally accepted TQM framework.

However, the Malcolm Baldrige Award are not based on empirical evidence".

Point 25: "Although there is

evidence that supports the effectiveness of TQM initiatives in organisations,

a large number of studies have shown that between 60% and 80% of TQM initiatives fail, or fail to have shown significant

impact on business performance".

|

The next

step is to relate the cognitive map variables to make up a cognitive map on Total

Quality Management. The cognitive map and its explanation are presented in the

next section.

A cognitive map on Total Quality

Management and its interpretation

By

relating the five variables identified in Table 2, the writer comes up with a

cognitive map on Total Quality Management (TQM), as shown in Figure 1.

These

cognitive map variables, five of them

altogether, are related to constitute a systemic image of Total Quality

Management. The links in the cognitive map (re: Figure 1) indicate direction of

influences between variables. The + sign shows that an increase in one variable

leads to an increase in another variable while a -ve sign tells us that in

increase in one variable leads to a decrease in another variable. If there no signs shown on the arrows, that

means the influences can be positive or negative. Readers are referred to the Literature on quality and excellence

Facebook page for more information

on the topic.

Concluding remarks

The

cognitive mapping exercise captures in one diagram some of the main variables

involved in Total Quality Management. The resultant cognitive map promotes an

exploratory way to study Total Quality Management in a holistic tone. The

experience of the cognitive mapping exercise is that it can be a quick,

efficient and entertaining way to explore a complex topic such as Total Quality

Management in business management. Finally, readers who are interested in

cognitive mapping should also find the article informative on this mapping

topic.

Bibliography

1.

Antony, J., C. Fergusson,

S. Warwood and J.H.Y. Tsang. 2004. "Comparing total quality management success

factors in UK manufacturing and service industries: some key findings from a survey"

Journal of Advances in Management Research

1(2): 32-45.

2.

Black, S. and L.J. Porter.

1995. "An empirical model for total quality management" Total Quality Management 6(2): 149-164.

3.

Chaudary, S., S.

Zafar and M. Salman. 2015. "Does total quality management still shine?

Re-examining the total quality management effect on financial performance"

Total Quality Management & Business

Excellence 26(7), Routledge: 811-824.

4.

Eden, C. and P.

Simpson. 1989. "SODA and cognitive mapping in practice", pp. 43-70,

in Rosenhead, J. (editor) Rational

Analysis for a Problematic World, Wiley, Chichester.

5.

Eden, C., C. Jones

and D. Sims. 1983. Messing about in

Problems: An informal structured approach to their identification and

management, Pergamon Press, Oxford.

6.

Flood, R.L. 1993. Beyond TQM, Wiley, Chichester.

7.

Gunasekaran. 1999. "Enablers

of total quality management implementation in manufacturing: a case study"

Total Quality Management 10(7): 987-996.

8.

Hackman, J.R. 1995. "Total

Quality Management: Empirical, Conceptual, and Practical Issues" Administrative Science Quarterly 40: 309-342.

9.

Literature on cognitive mapping Facebook page, maintained by Joseph, K.K. Ho (url address: https://www.facebook.com/Literature-on-cognitive-mapping-800894476751355/).

10. Literature on

literature review Facebook page, maintained by Joseph, K.K. Ho (url address: https://www.facebook.com/literature.literaturereview/).

11. Literature on quality

and excellence Facebook page, maintained by Joseph, K.K. Ho (url address: https://www.facebook.com/literature.quality.excellence/).

12. Lo, V.H.Y. and D. Sculli. 1995. "Industrial engineering and TQM"

Training for Quality 3(3), MCB University

Press: 4-7.

13. Managerial intellectual learning

Facebook page, maintained by Joseph, K.K. Ho (url address:

https://www.facebook.com/managerial.intellectual.learning/).

14. Mani, T.P., N. Murugan and C. Rajendran. 2003. "Classical approach to

contemporary TQM: an integrated conceptual

TQM model as perceived in Tamil classical literature" Total Quality Management 14(3), Routledge: 605-636.

15. Open University. n.d. "Sign graph" Systems Thinking and Practice (T552): Diagramming, Open University,

U.K. (url address: http://systems.open.ac.uk/materials/T552/) [visited at April

10, 2017].

16. Powell, T.C. 1995. "Total Quality Management as Competitive Advantage:

A Review and Empirical Study" Strategic

Management Journal 16(1) January: 15-37.

Pdf version at: https://www.academia.edu/32802767/Cognitive_mapping_the_topic_of_Total_Quality_Management_TQM_

ReplyDelete